As we step into the year 2024, the manufacturing landscape unfolds with distinct challenges that await companies on their tech journey ahead. To succeed, they must boost efficiency, cut costs, invest wisely, attract skilled employees, and prioritize streamlined communication for exceptional customer experiences. To meet these goals and others, manufacturers use a variety of solutions, including enterprise resource planning (ERP), manufacturing execution systems (MES), product life cycle management (PLM), supply chain management (SCM), quality management systems (QMS), and warehouse management systems (WMS).

In the following sections, we explore the general benefits of using the cloud by manufacturers and the specific benefits of using cloud computing services to support the various manufacturing solutions.

Benefits of Cloud Computing for Manufacturing

Manufacturing companies are using cloud solutions in increasing numbers each year. According to career site Zippia, “Between 2010 and 2020, the global cloud computing and hosting market size increased by 535%.” There are many compelling reasons for this rise.

#1 Improved Agility and Scalability

When manufacturers use on-prem solutions, their hardware investment may be hit or miss. If they don’t purchase enough, they may be unable to run intensive operations if their business ramps up. On the other hand, if they purchase too much, it may go unused when ramping down. Cloud platforms eliminate this conundrum with interconnected and flexible environments that scale up or down based on dynamic business requirements.

#2 Increased Data Accessibility

With real-time data accessibility, professionals from all departments can reach the information they need quickly and easily, no matter where they are or when they are working. This ease of access enhances decision-making and increases efficiency.

#3 Improved Collaboration

Cloud services enable seamless collaboration across company departments, locations, and external stakeholders such as supply chain partners. When manufacturers centralize data and operations in the cloud, they make it easier for teams to access and use it in real-time. Such enhanced collaboration upgrades communication, streamlines decision-making and supports cross-functional teamwork, which results in higher productivity and faster time to market.

#4 Increased Innovation

With advanced digital capabilities and platforms that support advanced analytics, machine learning, and the Internet of Things (IoT), cloud technology can serve to hasten innovation. For example, companies can use IoT-enabled tracking systems to accurately monitor and trace the location, status, and condition of their supplier’s materials.

#5 Greater Efficiency

Cloud-enabled systems allow manufacturers to integrate data streams from partners, platforms, and devices, resulting in a centralized record system that provides a single source of truth. Such streamlined systems are critical for developing insights that drive smarter and faster decision-making.

#6 Reduced Hardware and IT Costs

Cloud-based solutions reduce or eliminate capital expenditures associated with purchasing and maintaining on-prem equipment, such as servers, data storage devices, power supply equipment, and data centers. Instead, these costs can be converted to operating expenses, which are easier to manage and predict.

#7 Predictive Maintenance

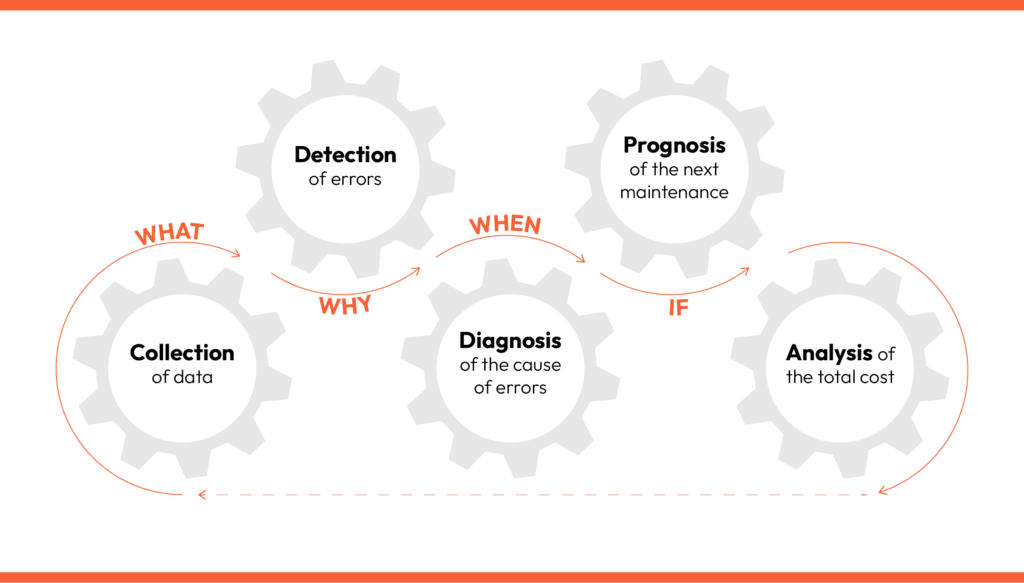

Cloud technology enables manufacturers to remotely monitor equipment to determine when they need to be repaired or replaced. The health and status of the equipment are uploaded to the cloud using wireless IoT devices, which are attached to the materials handling equipment. This enables greater efficiency in maintaining and replacing machines, which lengthens their lifespans and reduces costs.

Predictive maintenance is made possible by cloud computing.

#8 Real-time Supply Chain Management

Cloud-based supply chain management solutions enable manufacturers to track inventory levels, supplier details, and logistics in real-time. This allows companies to forecast demand, manage inventory, and streamline order fulfillment. They can coordinate with suppliers and distributors to ensure smoother operations and better customer service.

#9 Greater Productivity

With cloud use, manufacturers can forget about many aspects of traditional IT operations, including hardware purchasing, setup, and maintenance, as well as the risk of infrastructure failures and data security breaches. Instead, they can focus on the core aspects of their business that lead to innovation, differentiation, promotion, sales, and customer care.

#10 Improved Ability to Attract Talent

Young workers are accustomed to using digital applications in their personal lives, and they expect the same abilities while at work. Workers are attracted to using cloud-based applications that provide convenience and advanced capabilities.

#12 Better Cost-effectiveness

Manufacturers typically pay for cloud computing technology on a pay-as-you-go model. This eliminates the upfront hardware expenses associated with on-prem solutions and reduces the need for costly infrastructure upgrades. Additionally, cloud-based solutions provide automation that can optimize various processes, resulting in greater efficiency, reduced waste, and more effective resource allocation.

#13 Increased Security and Disaster Recovery

Cloud applications are less susceptible to cyberattacks than those hosted on on-prem hardware. The reason is that cloud-based computing services can use economies of scale to offer the highest security solutions and data encryption. Therefore, sensitive company and customer data remain safe and protected. These same security measures help manufacturers quickly recover from disasters or system failures.

Explore opportunities to enhance your manufacturing technology – reach out for a free consultation.

Types of Manufacturing Solutions

The following solutions are particularly useful to companies in the manufacturing sector, and when combined with cloud platforms, they deliver maximum benefit.

ERP

Enterprise resource planning (ERP) is a multi-featured system that integrates business processes across an organization. Its purpose is to streamline operations by providing a central location for various interconnected services. Modules may include finance, procurement, inventory management, production, sales, and HR. Cloud-based ERP systems can help manufacturers in the following ways:

- Eliminates redundancy in systems, which reduces wasted data entry and other process efforts, improving overall operational efficiency

- Promotes faster decision-making by giving professionals across the business real-time access to critical information

- Reduces costs by streamlining processes in areas such as inventory management, procurement, and labor

- Enhances compliance with regulatory requirements, reducing the likelihood of fines or other penalties

MES

Manufacturing execution systems (MES) serve as a bridge between ERP systems and real-time manufacturing operations to manage and monitor production processes. They may include work orders, scheduling, materials tracking, and data collection. Cloud-based MES can help manufacturers in the following ways:

- Enhances production processes by processing work orders, managing resources, and ensuring adherence to production standards

- Improves quality and maintains traceability with cloud computing tools that manage quality control and compliance

- Increases workforce efficiency by assigning tasks, tracking team member productivity, and delivering instructions to operators.

- Promotes efficiency by analyzing performance metrics and identifying obstacles, inefficiencies, and areas for improvement

PLM

Product life cycle management (PLM) solutions enable manufacturers to manage critical product life cycle procedures. They include design for manufacturing, production enablement, maintenance, and disposal. Cloud-based PLM can help manufacturers in the following ways:

- Enables dispersed teams to collaborate on product design and development, leading to faster time to market

- Allows scalability, making these solutions suitable for operations of any size and those that are quickly growing

- Enables users to access and manage the solutions from anywhere at any time, offering convenience and flexibility

- Supports spending reduction efforts by reducing up-front and maintenance costs as compared to labor-intensive on-prem solutions

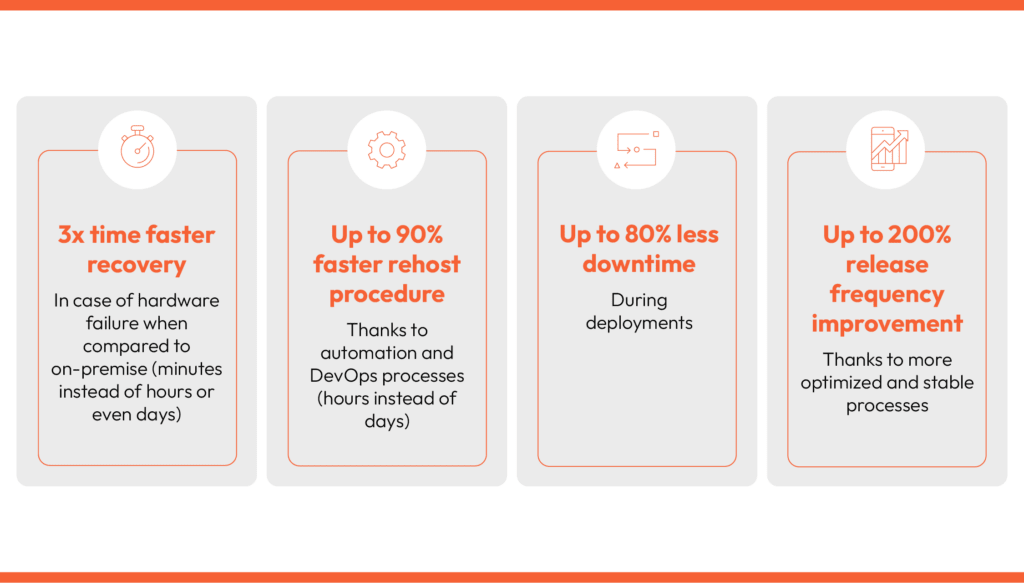

Measured benefits in the product life cycle management (PLM)

SCM

Supply chain management (SCM) systems can help manufacturers to manage their supply chains more effectively. Specifically, they support efforts in procurement, inventory management, demand forecasting, and logistics optimization. Cloud-based SCM can help manufacturers in the following ways:

- Helps companies make smarter decisions and serve customers better by providing real-time visibility into supply chain data

- Provides flexibility and makes adapting to changing business needs easier by enabling integration with other cloud-based services and applications

- Enables seamless collaboration with suppliers, distributors, and other supply chain partners

- Provides data and predictive analysis to help companies optimize supply chain operations, leading to greater efficiency and better customer care

QMS

Quality management systems (QMS) help manufacturers ensure products meet quality and compliance standards and regulations. Cloud-based QMS can help manufacturers in the following ways:

- Helps companies ensure compliance with industry regulations and standards to avoid fees and other consequences

- Enables streamlined processes by providing effective document control and version management

- Provides flexibility and efficiency by allowing authorized personnel to access quality data and reports

- Allows the efficient planning, execution, and tracking of quality processes as well as internal and external audits

WMS

Warehouse management systems (WMS) help manufacturers streamline warehouse operations with inventory management, order picking, packing, and shipping features. These procedures improve distribution and logistics processes. Cloud-based WMS can help manufacturers in the following ways:

- Supports global warehouse operations by providing accessibility to critical data and tools from various locations.

- Provides real-time visibility into inventory levels, warehouse operations, and order fulfillment, enabling better decision-making and responsiveness.

- Facilitates collaboration among warehouse staff, suppliers, logistics partners, and eCommerce partners through shared access to real-time information on inventory movement and order status

- Streamlines warehouse operation, automating manual processes, reducing errors, and increasing overall efficiency in picking, packing, and shipping.

Source: Markets and Markets

Cloud Technology is Perfect for a Changing Manufacturing Landscape

As technological advancements and shifting market dynamics force the manufacturing industry to evolve, staying on top of operations is always more critical. While many manufacturers continue to make good use of traditional on-prem solutions, cloud-based options have emerged as powerful tools. These solutions provide numerous benefits, such as streamlining processes, enhancing efficiency, and remaining compliant with regulation requirements, leading to enhanced competitiveness.

Additionally, cloud-based options, including public, private, and hybrid clouds, as well as XaaS offerings, allow companies to customize their infrastructures to their unique needs and compliance requirements. These solutions are restructuring the way manufacturing is done by offering scalability, cost-efficiency, real-time data access, and global collaboration.

Manufacturing solutions that harness the power of the cloud — including ERP, MES, PLM, SCM, QMS, and WMS — help to optimize various aspects of manufacturing operations, from design and production to supply chain management and quality assurance. The cloud component offers greater flexibility, convenience, cost-effectiveness, and security.

As all industries strive for greater digitalization in their operations, cloud-based manufacturing solutions are becoming less of a choice and more of a strategic imperative. Implementing cloud computing enables manufacturers to adapt quickly to market changes, respond to customer demands, and achieve new levels of innovation. With the continuous advancement of technology, those who take advantage of these capabilities will stay on top of their manufacturing operations and, beyond that, shape the industry’s future.