Your BOM’s a mess. Your team missed another order. Raw materials vanish into thin air. If that sounds a little too familiar, it’s time for smarter tools.

A manufacturing business that still uses spreadsheets for production planning is walking a tightrope blindfolded. Without proper production management software, you’re not really managing. You’re surviving.

Even lean teams lose hours to shop floor lag when they can’t track production data in real time. Taiichi Ohno wouldn’t tolerate it and neither should you. (He would say you’re automating waste.) Today’s tools offer digital help to streamline operations without micromanaging.

Modern production planning software swaps out guesswork for clarity. It fits schedules to inventory management across your enterprise resource planning stack. The right tools can end the fire drills and help you build a process Honda would be proud of.

What Is Production Management Software?

Production management software gives manufacturers visibility into how they plan, track, and control production. It brings together key components like scheduling, inventory, quality, and coordination to cut out manual errors and missed deadlines.

These solutions integrate with MES (Manufacturing Execution Systems) and ERP platforms to automate workflows and reduce downtime. They work like Gantt charts without the gridlock. Instead of reacting to delays, you’re directing every step.

Production managers use the real-time data from these tools like a digital gemba walk. They can see data points like moving materials, stuck tasks, and processes that are about to go wrong. Used right, production management software lets you act on insights instead of instincts.

Tool Breakdown: Find the Right Fit for Your Workflow

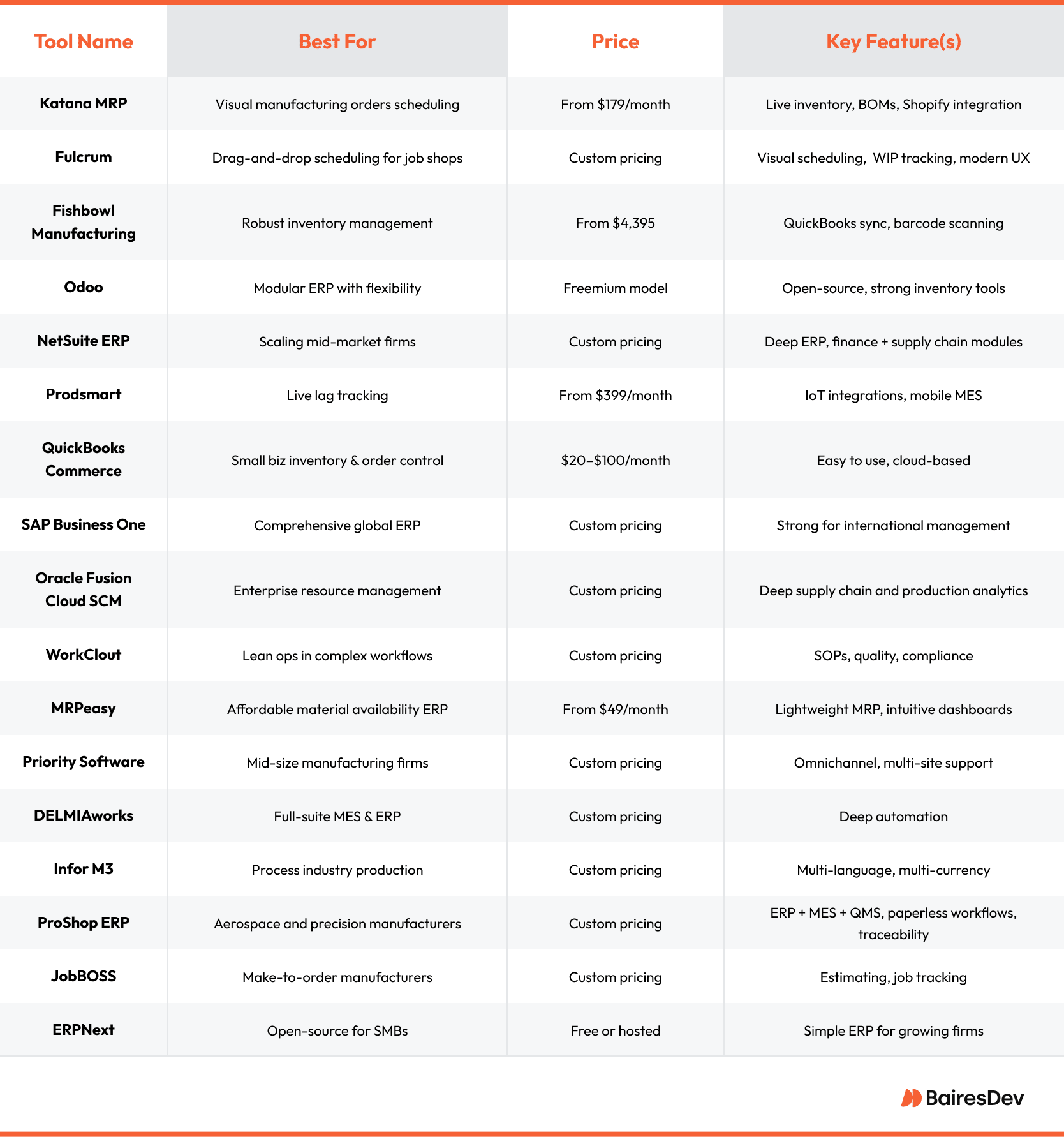

Tim Cook is so good he could almost manage global supply chains with spreadsheets. In the real world we need better tools. This table compares the top 20 production management software tools to get the right fit fast. They can help you manage inventory levels, Gantt charts, and end lag.

Top Production Management Software Tools

Here’s a more detailed overview of the top production planning software options on the market. Each one is designed for different team sizes, workflows, and shop floor needs. Whether you’re a small manufacturer or scaling enterprise, this list helps you cut through ERP fatigue and find the right fit.

Katana MRP

Not all tools solve the same problem. This one’s best for small manufacturers that want immediate clarity sans clutter. Katana MRP delivers visual simplicity and power for production planning. What it doesn’t do is swamp you with features you won’t use.

- Price: From $179/month

- Key features:

- Visual production schedules

- Inventory tracking of raw materials and finished goods

- Seamlessly integrates with Shopify and QuickBooks

Fulcrum

Tired of clunky Gantt charts that don’t reflect what’s really happening in your facility? Fulcrum gives job shops a drag-and-drop command center with real-time visibility and modern design.

- Price: Custom pricing

- Key features:

- Visual scheduling with live WIP tracking

- Real-time data from floor operators

- Modern UI designed for fast-paced production environments

Fishbowl Manufacturing

When inventory chaos keeps crashing your production schedule, Fishbowl steps in. It’s purpose-built to bring order to reordering, restocking, and raw materials tracking, especially for QuickBooks users.

- Price: From $4,395 (one-time)

- Key features:

- Real-time inventory and reorder points

- Sales and purchasing automation

- QuickBooks integration

Odoo

Need manufacturing tools that grow with you? Odoo’s open-source ERP lets small teams start simple and scale fast, adding modules as workflows get more complex.

- Price: Freemium model

- Key features:

- Modular ERP with production planning tools

- Dashboards for productivity tracking

- Easily scales with your sales and purchasing needs

NetSuite ERP

Mid-market manufacturers looking to streamline without losing agility often land here. NetSuite ERP connects finance, sales, and supply chain in one flexible platform.

- Price: Custom pricing

- Key features:

- Full ERP including scheduling and sales

- Real-time data visibility across departments

- Integrates with CRM and e-commerce

Prodsmart

If your data lives in clipboards and coffee-stained binders, Prodsmart can fix that. It turns every machine and operator into a live data feed. It’s MES without the usual overhead.

Price: From $399/month

Key features:

- Production data and traceability

- MES and mobile-friendly dashboards

- Shop floor lag prevention

QuickBooks Commerce

Running QuickBooks already and tired of juggling separate inventory tools? QuickBooks Commerce ties together purchasing, order tracking, and inventory for small manufacturers who need simplicity that sticks.

Price: $20–$100/month

Key features:

- Inventory management for small manufacturers

- Syncs with QuickBooks financials

- Simplifies purchasing and order tracking

SAP Business One

If you’re big enough to need global coordination but not ready for enterprise bloat, consider SAP. Their Business One production management software offers the depth and compliance support of a full ERP, scaled for growing operations.

Price: Custom pricing

Key features:

- Comprehensive production schedules and purchasing

- Seamlessly integrates with CRM

- Deep reporting for time-sensitive decisions

Oracle Fusion Cloud SCM

For scaling fast and managing global supply chains, Oracle Fusion brings enterprise-grade forecasting, resource planning, and compliance. It’s a good fit for operations with complex sourcing and distribution demands.

Price: Custom pricing

Key features:

- AI-powered production planning software

- Real-time sales and raw materials forecasting

- Global compliance and supply chain tools

WorkClout

If compliance chases are draining your bandwidth, WorkClout can help. It’s built for manufacturers that need documentation, SOPs, and quality control woven directly into daily activity. Saving your team from scattered spreadsheets and paper trails, this platform consolidates everything into one interface.

Price: Custom pricing

Key features:

- SOPs, quality tracking, continuous updates

- MES functionality for scheduling and planning

- Integrates across departments

MRPeasy

Want serious scheduling and materials control without the weight of enterprise ERP? MRPeasy is a cloud-based MRP designed for small manufacturers who need clarity and speed without overkill. It strikes a balance between affordability and depth, offering core planning, BOM tracking, and order management.

Price: From $49/month

Key features:

- Cloud-based MRP with real-time data access

- Integrates with ecommerce and accounting platforms

- Ideal for shop floor activities and raw materials control

Priority Software

If your midsize operation is outgrowing its current system, Priority Software is a useful ERP solution. It handles everything from materials planning to production tracking in a streamlined platform built for scale. Teams benefit from continuous coordination without unnecessary complexity.

Price: Custom pricing

Key features:

- Dynamic dashboards and alerts

- Strong scheduling and purchasing automation

- Scales with growing operational demands

DELMIAworks

Built for high-volume output and complex workflows, DELMIAworks is a full-suite MES and ERP system. It provides automation, production insights, and end-to-end operational control. Designed for manufacturers with demanding throughput and compliance needs, it also supports continuous improvement with visibility into every process.

Price: Custom pricing

Key features:

- Live production data for proactive decision-making

- Integrated modules for sales, purchasing, and inventory

- Designed for scheduling and continuous improvement

Infor M3

Process manufacturers juggling international operations turn to Infor M3 for its powerful multi-site, multi-language, multi-currency capabilities. It’s tailored for industries like food, chemicals, and fashion, where production complexity and regulatory demands require flexible ERP systems.

Price: Custom pricing

Key features:

- Strong in chemical and food manufacturing

- Integrates with multiple CRMs and ERPs

- Advanced scheduling and purchasing logic

ProShop ERP

ProShop is for manufacturers that need ERP, MES, and QMS all in one. It’s especially valued by aerospace, defense, and precision shops. It excels at traceability, compliance, and control in a bloat-free platform.

Price: Custom pricing

Key features:

- Integrated ERP, MES, and QMS for regulated industries

- Paperless job travelers and up-to-the-minute work center tracking

- Built for small to mid-sized U.S. manufacturers

JobBOSS

Job shops and custom manufacturers turn to JobBOSS for its ability to track production times, costs, and estimates in real time. It’s built for flexibility, giving operations clear visibility without locking them into rigid workflows or oversized ERP systems.

Price: Custom pricing

Key features:

- Dynamic job tracking and costing

- Visual dashboards for scheduling and productivity

- Focused on shop floor activities and quoting accuracy

ERPNext

ERPNext is an open-source ERP that offers surprising depth for small manufacturers. It covers everything from sales to production without expensive licenses or complex deployments, making it a handy choice for agile teams ready to own their stack.

Price: Free or hosted

Key features:

- Built-in modules for sales, purchasing, and scheduling

- Live dashboards and mobile-friendly interface

- Low-code customization

Beyond the Tools

The best ERP system in the world won’t reduce downtime if no one knows how to use it. A sharp lead who knows how to read production data and assign priorities can make or break your production planning.

In lean teams, the “task jockey” is the glue between your tools and your people. They coordinate equipment usage, control inventory flow, and track finished products. Without that person, even the most essential components can get lost. With them, your customers will feel the difference in cost, product quality, and delivery speed.

Production Planning Software Mistakes to Avoid

Disaster. Your rollout’s falling apart. What went wrong? You sourced and bought an excellent production planning tool, but sadly, you skipped the stakeholder input and training steps. Unfortunately, crossed fingers and top-down leadership are not a phased plan. That strategy can turn good planning tools into shelfware. This section shows the most common mistakes that kill ROI and how to avoid them.

Skipping stakeholder input

When you’re rolling out production management software, leaving end users out of planning discussions is a fast track to failure. From the production floor to inventory teams, everyone who touches the system should weigh in. This creates early buy-in, exposes gaps in workflow logic, and sets a stronger foundation for your manufacturing business.

Over-customizing too soon

It’s tempting to tweak every feature before go-live. But this often leads to process bloat that kills production efficiency. Stick close to out-of-the-box tools at first. Tools like Odoo and Fishbowl Manufacturing are designed to serve most use cases under one roof—use them that way before layering complexity.

Undertraining your team

A system is only as good as the people using it. Skimping on training results in slow adoption, missed materials data, and eventual system rejection. Use “The Dailies” and frequent check-ins to reinforce workflows and reduce production bottlenecks over time.

Launching all at once

A big-bang launch can crash even the best systems. Go phased. Use agile lite methods, especially in multi-site operations. This lets you catch early errors, keep operations steady, and reduce downtime on the production floor.

Tips From the Floor: What Real Managers Recommend

When production planning breaks down, it’s rarely the software’s fault. Missteps like skipping training or over-customizing early can wreck adoption. Fixing them takes clarity and coordination like stepping into the pages of The Goal.

- Automate repetitive tasks: Use click-to-complete workflows to cut downtime and keep equipment focused on finished products. Tools like Prodsmart make this easy in daily operations.

- Assign a lead: A production management software tool alone won’t manage your ERP system. Designate a “task jockey” to oversee inventory, materials, and scheduling. This adds top-down oversight and real accountability.

- Use sub-boards and visual scheduling: Katana MRP can help you manage manufacturing orders and inventory levels using Kanban boards. Just beware sub-board creep where visual scheduling gridlock slows your team.

- Don’t fear cloud solutions: Many lean and mean operations are ditching on-premise tools for cloud-based platforms. From inventory management to BOM tracking, the right software reduces clutter and boosts management visibility.

Ready to scale your factory workflow?

The right production management software gives you better access to data, clearer planning, and tighter control over inventory and materials. But without a rollout plan, the best features will sit idle.

Focus on tools that support your current operations and scale with you. BairesDev helps mid-sized manufacturers eliminate production slowdowns, reduce inventory fire drills, and streamline purchasing with real-time tools like Katana MRP. From planning to execution, we implement features that actually boost productivity. Let’s talk.