Forget the buzzwords for a minute. Most engineering leaders aren’t just looking for smarter ways to run their organization, they are trying to stop their teams from getting slower.

Continuous improvement isn’t some abstract mindset. It’s a core engineering discipline. In software, it’s the crucial system that underpins everything in Agile and DevOps, and it’s the only thing that prevents teams from getting bogged down by their own success.

The payoff is speed, stability, and less firefighting. But it requires more than talk. Let’s break down what it actually takes to make this work.

Fundamentals of Continuous Improvement

Continuous improvement is about making steady, ongoing improvements across every part of the business.

It focuses on spotting opportunities for small, incremental change, and then acting on them. Over time, these small adjustments add up to big results.

This concept is a cornerstone of many management systems, including Total Quality Management (TQM) and the Lean methodology. When implemented consistently, continuous improvement can help eliminate waste, reduce errors, and raise service quality.

You can look at it as an ongoing journey. It requires a commitment to regularly evaluating and refining operations to meet evolving customer expectations and market conditions.

Incorporating Incremental Improvements

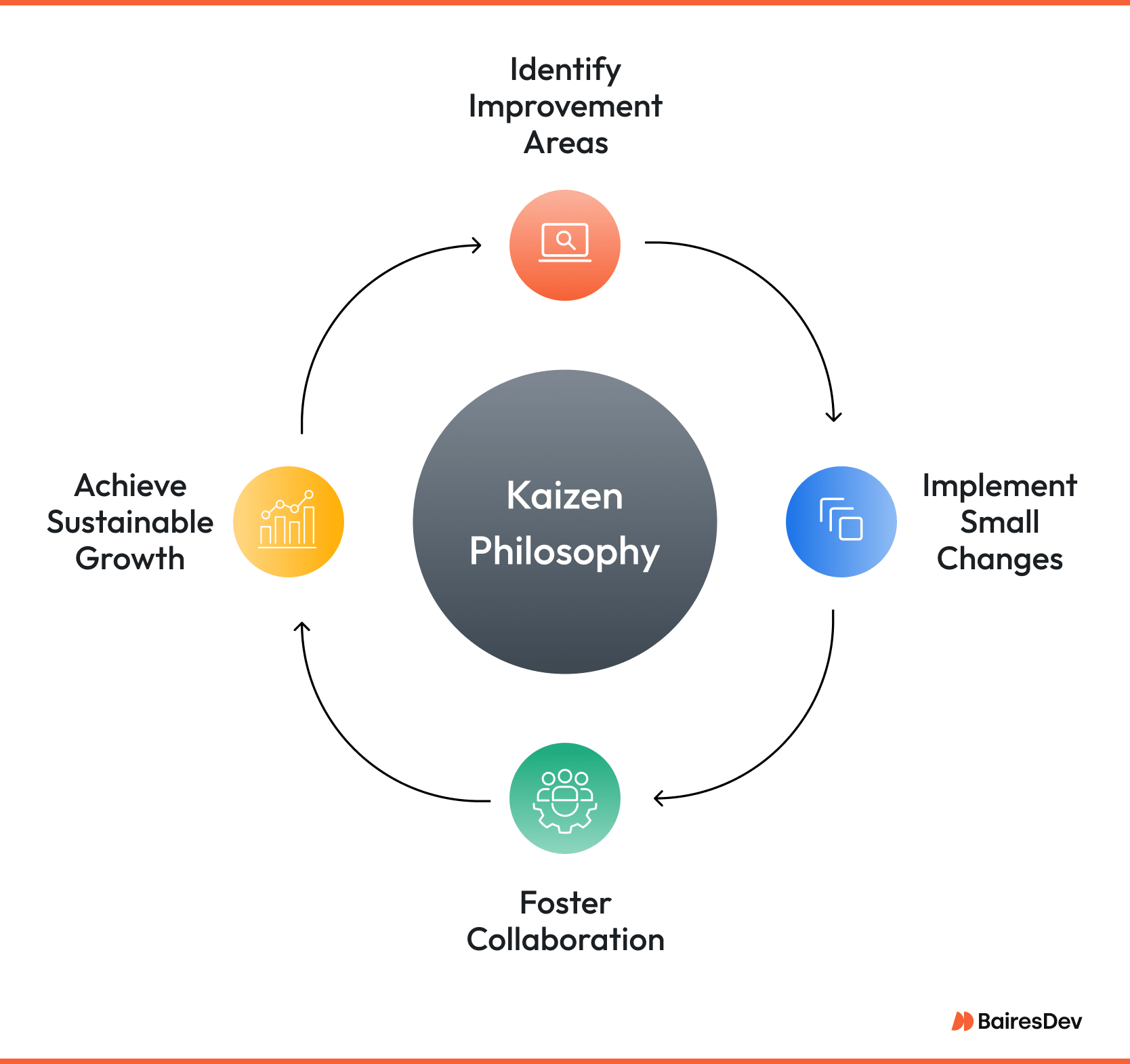

A helpful way to think about continuous improvement is also through the lens of Kaizen, a Japanese term meaning “change for the better.” This philosophy emphasizes involvement from everyone—not just leadership—to drive meaningful progress. Toyota famously used this model to revolutionize its manufacturing practices.

Continuous improvement also aims to reduce waste and increase value. That could mean something as simple as cutting excess steps in a process or removing friction points that slow teams down.

The goal? A more efficient, value-driven organization.

Guiding Principles

At the heart of this approach is the idea of making manageable changes repeatedly. This involves a systematic approach to analyzing data and implementing changes on a small scale.

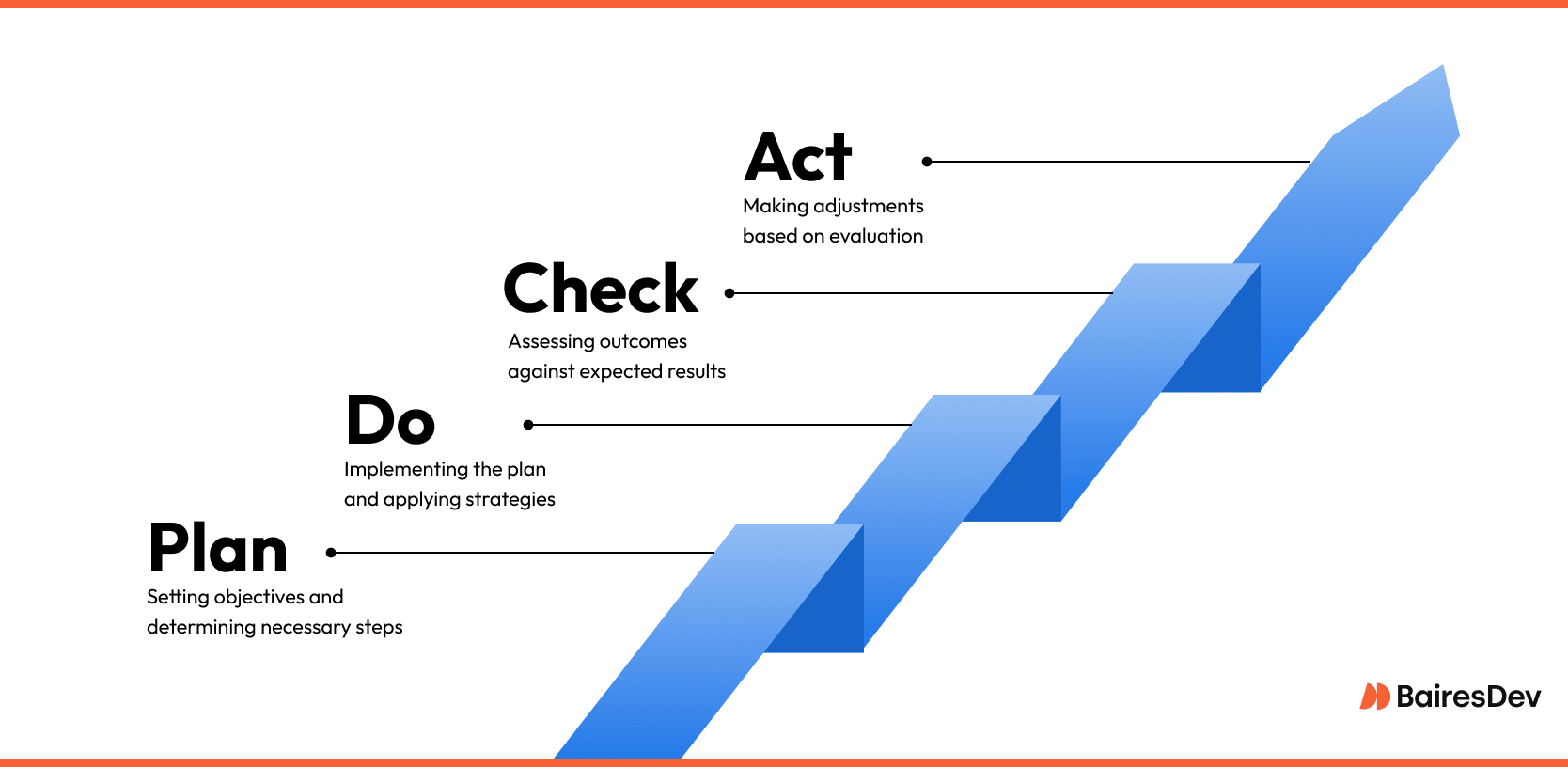

The Plan-Do-Check-Act (PDCA), also known as the Deming Cycle, provides a repeatable framework for this kind of change. Here’s how it works:

- Plan: Identify a goal or process to improve.

- Do: Test a small change.

- Check: Measure the results of the test.

- Act: Scale the change, or adjust it based on what you learned.

This cycle makes it easier to track progress, adjust course when needed, and keep moving forward.

It’s especially effective when backed by employee involvement. When all parties involved are on the same page and actively contributing ideas, the organization can more effectively identify areas for improvement and implement changes. This collaborative approach ensures that the improvement process is comprehensive and inclusive.

Continuous Delivery and Continuous Improvement: What’s the Link?

Though not the same thing, continuous delivery is closely related to continuous improvement.

Continuous delivery focuses on rapidly producing and releasing updates with minimal delays. It’s a core part of Agile and DevOps, and often involves automated workflows and frequent iterations.

In many ways, continuous delivery depends on continuous improvement. Without a commitment to refining processes, identifying bottlenecks, and iterating based on feedback, it’s hard to maintain delivery at speed without sacrificing quality.

Tools Help, But People Drive Change

Many continuous improvement tools can help businesses embrace new processes confidently:

- Kanban boards: Help teams visualize their work, reduce bottlenecks, and improve task flow.

- Agile methodologies: Encourage iterative work, allowing for constant feedback and adaptation.

- Root Cause Analysis: Helps identify and solve underlying issues rather than treating surface symptoms.

- Software solutions: Tools like Businessmap and SolveXia automate parts of the improvement process, saving time and improving accuracy.

Jira, Confluence, Slack workflows, DORA dashboards are enablers. But tools don’t drive improvement. People do.

Why Ad Hoc Doesn’t Scale

Teams often try to improve “when there’s time.”

But that makes improvement optional, which means it won’t survive crunch periods or shifting priorities. Worse, if you rely on a few individuals to spot inefficiencies, knowledge stays siloed.

Leaders who systematize improvement by linking it to Agile rituals, team KPIs, or delivery reviews get compounding returns. Each cycle gets a bit tighter, and each engineer wastes a bit less time. Across 100+ people, this ongoing effort adds up.

What Does Continuous Improvement Look Like in Practice?

So, how does continuous process improvement show up in real business environments? Here are some common traits of organizations that embrace this mindset:

- Employees at all levels are encouraged to share feedback and suggest improvements.

- Ongoing evaluation of current processes is the norm.

- No workflow is treated as static; everything is subject to review.

- Open communication is prioritized through regular updates, meetings, and digital tools.

- Stakeholders stay informed and involved throughout change initiatives.

- Progress is measured frequently, and plans are adjusted based on real-world results.

- Small wins are celebrated, and small changes are tested before wide rollout.

- Team members take ownership, while leaders help guide and align improvement efforts.

- Continuous improvement is integrated into daily routines, not just quarterly reviews.

- Quick, actionable fixes are prioritized when possible.

- A Lean mindset is encouraged throughout the business.

- The philosophy becomes a natural part of the company’s culture.

Of course, this model can be adjusted based on your industry, size, or specific challenges, but the core ideas remain the same.

How Agile Promotes the Continuous Improvement Model

Agile focuses on small, incremental changes that lead to measurable results over time, as described in some of the principles:

- Our highest priority is to satisfy the customer through early and continuous delivery of valuable software.

- Continuous attention to technical excellence and good design enhances agility.

According to the 2020 State of Agile Report, accelerating software delivery and enhancing the ability to manage changing priorities were the most-cited reasons for turning to agile, with the majority of respondents calling them the top impetuses.

Agile is also a mindset, one that must embrace the idea of constantly improving products and processes. It’s about adapting to serve particular situations to the best of a team’s capacity and making progress toward achieving their goals in the process.

By improving and streamlining processes, Agile teams can boost operational efficiency and deliver high-quality results more quickly.

Agile requires flexibility, which goes hand in hand with the idea of continuous improvement. Feedback is another important aspect of Agile, and when teams receive and act on that feedback, they are seeking to improve the way they work and the products they put forth.

Building a Continuous Improvement Culture

You don’t need a Kaizen consultant or another weekly meeting. What you need is:

- A clear owner for follow-through from retros

- Time explicitly allocated for trying improvements

- A process for reviewing what worked and what didn’t

Start small. Improve one thing per team, per sprint. Track the impact. Make it normal. When improvement becomes routine, velocity follows.

A continuous improvement culture fosters increased efficiency, improved quality, and reduced waste. To truly benefit from this approach, your organization needs to build a culture that supports it.

This starts with leadership commitment, but it extends to every level of the company. It requires considerable effort to create a supportive environment.

This means establishing a continuous improvement mindset, where all employees are encouraged to identify areas for improvement and suggest new ideas. Providing training and resources, such as workshops on the PDCA cycle and Lean methodology, is crucial to support continuous improvement.

When that mindset takes root, businesses gain resilience, innovation, and long-term growth.

The Benefits of Continuous Improvement Methods

Continuous improvement could be seen as a practical approach that helps businesses stay sharp and responsive.

When teams regularly reflect on how they work and look for small ways to do things better, the impact adds up. Processes become smoother, people grow more confident in their roles, and customers notice the difference.

Over time, this mindset builds a stronger, more adaptable organization, one that’s ready for whatever comes next. Perhaps this is why so many businesses have made it the gold standard at their organizations.

Frequently Asked Questions

My CFO only sees time not spent on features. How does this actually lead to cost savings?

Inefficiency is a tax on your payroll. A good continuous improvement process reclaims wasted developer hours from manual tasks and recurring bugs. The cost savings are immediate: you’re not losing feature time, you’re buying back future development capacity.

How do we measure whether it is working?

Track relevant metrics, such as cycle time, defect rates, team throughput, customer satisfaction. Revisit them regularly. Improvement should be visible in day-to-day operations, not just KPIs.

Do we need to adopt Agile or Lean to implement a continuous improvement program?

No, but they help. Agile and Lean provide structured ways to implement continuous improvement. That said, you can start small: review recurring pain points, test small process changes, and measure results.

We’re swamped. What’s a practical first step that won’t derail our current roadmap?

Make the work visible. If you use the Kanban method, add an “Improvements” swimlane. Create a simple rule: ‘For every four feature cards, we do one improvement card.’ This forces you to implement small improvements and makes it part of the daily workflow, not a separate project.

What’s the most common reason continuous improvement efforts fail?

Lack of follow-through. Teams run retrospectives but don’t act on the findings, or they try to overhaul too much at once. Small, consistent steps with feedback and accountability are more sustainable.

Should the process be centralized or team-driven?

Both. Teams should identify and own local improvements. But without a broader strategy and cross-team alignment, silos can form. A hybrid model usually works best.